8 Easy Ways To Attach Furniture Feet

Our furniture feet can be used under beds, sofas, cabinets, book cases, chests of drawers, case pieces, upholstered chairs, ottomans, risers, media cabinets, and more. When you buy feet from us, you’ll be able to select from attachment options that work best for that foot. Here are 8 ways how to attach furniture feet:

1. Dowel Screws

A ¼” x 2” dowel screw is installed part-way into the foot, the remaining 7/8” of exposed threads allow you to screw the foot directly into the underside of your furniture. A fast, easy and inexpensive solution, but only as strong as the material you are attaching the foot to.

Recommended for:

- Easy, fast and inexpensive installation

- An invisible means of affixing feet—all you’ll see is the foot itself when installed

- Shorter feet attached to solid or dense wood bases

Not recommended for:

- Longer and thinner feet

- Heavy load bearing

- Furniture that gets moved or slid across the floor frequently

- Furniture with metal or softer wood bases

How to order:

We can install the dowel screw into your furniture feet—it is offered as an optional attachment service when you buy any foot where dowel screws are a workable solution. You can also buy dowel screws separately.

2. Threaded Inserts

Threaded inserts take a little woodworking skill. They are installed directly into the underside of your furniture, allowing any foot with a 3/8” wide insert bolt to be installed. The feet can then be easily unscrewed for storage and transport. A rugged and invisible solution, strong enough for any application.

Recommended for:

Not recommended for:

How to order:

View our threaded inserts here. If you’d like your feet to come with the compatible Threaded Insert Bolts preinstalled, simply add a Cleat/Mounting Bolt Installation service for each part you order.

3. T-Nuts

T-Nuts are installed from the top of your mounting surface, rather than the underside. This creates an incredibly strong connection, preferred by many professionals. A bolt is installed part-way into the foot, the remaining exposed threads are screwed into the T-Nut. The feet can be easily unscrewed for storage and transport. A rugged and invisible solution, strong enough for any application

Recommended for:

Not recommended for:

How to order:

T-Nuts are offered as an optional service when you buy any of our wooden feet. We will install the bolt in your foot and supply the T-Nut. View our T-Nuts here. For table legs and columns, add one T-Nut Bolt Installation Service for each part you order.

4. Straight and Angled Metal Plates

Metal plates attach to the underside of your furniture with 4 screws (supplied). A bolt is installed part-way into the foot, the remaining 5/16” of exposed threads are screwed into the metal plate. The feet can be easily unscrewed for storage and transport. A fast, easy, and inexpensive solution, well suited for lighter duty applications. Available for both straight and angled attachments.

Recommended for:

- Easy, fast and inexpensive installation

- Longer and thinner feet attached to solid or dense wood bases

- An invisible means of affixing feet—all you’ll see is the foot itself when installed

- Angled or straight attachments

Not recommended for:

- Heavy load bearing

- Furniture that gets moved or slid across the floor frequently

- Furniture with metal or softer wood bases

- Feet 2.25” diameter or more

How to order:

Metal plates are offered as an optional attachment service when you buy any foot where they are a workable solution. We install the hanger bolt into your furniture feet for you. You can also buy the metal plates separately.

Straightmetal attachment plates

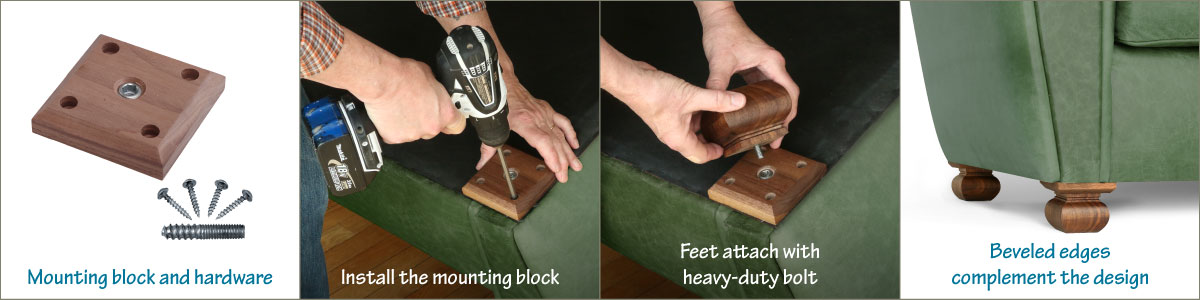

5. Wood Mounting Blocks

Mounting blocks are offered in 7 species of wood and in 2 sizes. They attach to the underside of your furniture with 4 screws (supplied). A 3/8” x 2 ½” bolt is installed part-way into the foot, the remaining ¾” of exposed threads are screwed into the mounting block. The blocks have crisp beveled edges for a more attractive presentation. The feet can be easily unscrewed for storage and transport. A fast and easy solution, strong enough for almost any application.

Recommended for:

- Easy and fast installation

- Feet attached to wood bases

- Heavy load bearing

- Furniture that gets moved or slid across the floor frequently

- Square or round feet

Not recommended for:

- Furniture with metal bases

- Applications where you want the attachment hardware to be less visible

How to order:

Mounting blocks are offered as an optional attachment service when you buy any foot where they are a workable solution. We will install the hanger bolt into your furniture feet for you. The blocks will be the same species (and finish) as the feet you order. You can also buy Wood Mounting Blocks separately from us.

6. Straight and Angled Cleats

Cleats were developed as an attractive and sturdy way to affix Mid-Century Modern legs to table tops without using aprons. The cleats—which come in 8 lengths from 12” to 36”—attach to the underside of your furniture using the supplied screws. Feet attach at each end of the cleat; 1 cleat for 2 feet. A hanger bolt is installed half-way into the foot, the remaining exposed threads are screwed into the cleat. The feet can be easily unscrewed for storage and transport. A fast and easy solution, strong enough for any application. Choose straight cleats or angled (splayed) cleats for a classic Mid-Century Modern look.

Recommended for:

- McCobb and Wegner feet

- Easy and fast installation

- Feet attached to wood bases

- Heavy load bearing

- Furniture that gets moved or slid across the floor frequently

Not recommended for:

- Furniture with metal bases

- Applications where you want the attachment hardware to be less visible

How to order:

For our popular McCobb Mid-Century Modern and Wegner Danish Modern designs, you can order feet and cleats as sets. You’ll choose the length of the cleat and the height of the feet, available in 4 species, unfinished or finished with Monocoat NaturalOil. Each set includes 2 cleats, 4 feet with the cleat bolt installed, and screws to attach the cleats to the underside of your furniture. You can also buy cleats separately from us.

McCobbMid-Century Modern Feet & Angled Cleat Set (4 Feet & 2 Cleats)

McCobbMid-Century Modern Feet & Straight Cleat Set (4 Feet & 2 Cleats)

WegnerDanish Modern Feet & Angled Cleat Set (4 Feet & 2 Cleats)

WegnerDanish Modern Feet & Straight Cleat Set (4 Feet & 2 Cleats)

7. Single Angled Cleats

Single angled cleats were created specifically to complement our McCobb and Wegner feet. They attach to the underside of your furniture using the supplied screws. A 3/8” x 2 ½” bolt is installed part-way into the foot, the remaining ¾” of exposed threads are screwed into the cleat. The feet can be easily unscrewed for storage and transport. A fast and easy solution, strong enough for any application.

Recommended for:

- McCobb and Wegner feet

- Easy and fast installation

- Feet attached to wood bases

- Heavy load bearing

- Furniture that gets moved or slid across the floor frequently

Not recommended for:

- Furniture with metal bases

- Applications where you want the attachment hardware to be less visible

How to order:

Single angled cleats are available in 4 species, unfinished or finished with Monocoat Natural Oil. Each cleat comes with 4 mounting screws.

8. Direct Attachment

Metal furniture feet require no additional parts or service to attach—they can be affixed directly to the bottom of your furniture with the supplied screws.

Recommended for:

- Contemporary designs

- Easy and fast installation

- Feet attached to wood bases

- Heavy load bearing

- An invisible means of attaching your furniture feet

- Furniture that gets moved or slid across the floor frequently

Not recommended for:

- Furniture with metal bases

- Traditional designs

How to order:

View all our metalfurniture legs here